Industries

Medical & Healthcare

Medical EquipmentThermoformed medical equipment covers enable clean and dry storage of medical instruments and equipment, including IV pumps, ventilators and liquid oxygen system covers. This plastic sheet molding process is a reliable method of producing the high-quality products needed for the medical industry.

Agriculture

Agriculture EquipmentsThe plastic sheet molding process of vacuum forming is also used to create various types of agricultural equipment and components, including panels, roofs, interior components for tractors and farm machinery, sprayer shells, feed/water containers and livestock housings. It often works better than sheet metal components because of the equipment's exposure to UV radiation and elements and plastic resins' resistance to corrosion.

Mass Transit

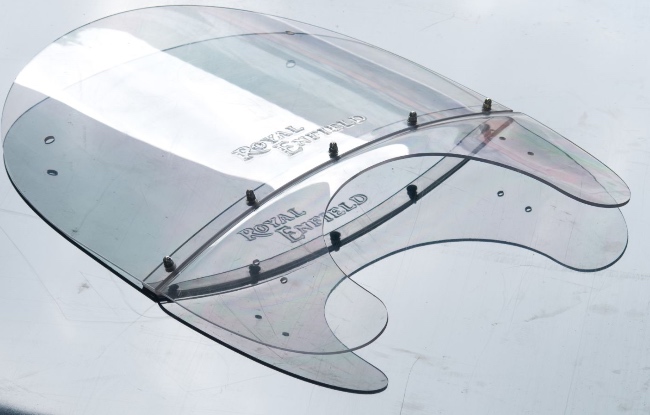

Automotive ComponentsAutomotive components including panels, doors, seating parts, dashboards, bumpers, air ducts, truck bed liners, floor mats and headlight covers are all ideal applications for thermoformed plastics. Vacuum forming is best for the larger, shorter-run components (such as bumpers and interior panels), while pressure forming brings out precise, sharp details and attractive surfaces when needed (such as parts with logos stamped in).

Architecture & Interior

Skylights & Roofing SolutionsBrightening a room with a skylight can easily be accomplished using plastic sheet molding, in part because it's actually more transparent than glass and shatterproof grades are available. Skylights may be vacuum formed or drape formed, depending on the shape and aesthetic needs of a particular application.

Textile

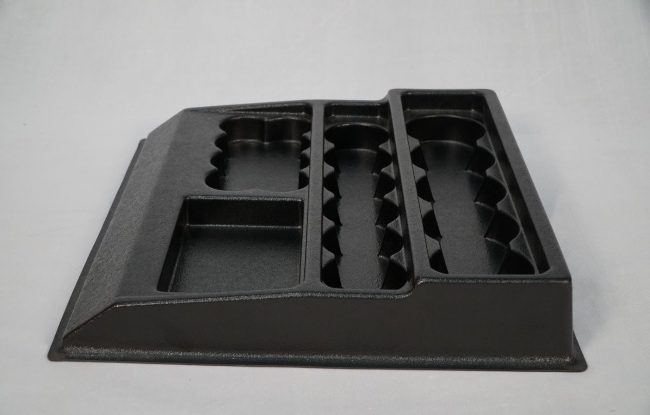

Machine Parts & CoversPlastic Thermoforming is an ideal choice for the Machine parts and covers for the textile industries, as some requirements include Transparent Flow ducts fixed on an already thermoformed ABS part, making Intricate assemblies possible with the Adhesive tech. Acros has been servicing the Textile Industry for the last 22 years and has enough experience and knowledge of the process to provide you with best pocket friendly parts, even on limited quantity runs.

OEM

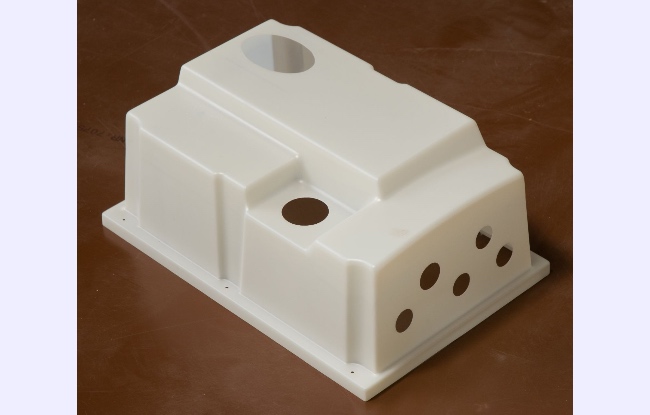

Components & CoversThermoformed equipment covers offer protection from impact, the elements, ultraviolet (UV) radiation and corrosion to all types of equipment with faster lead time to production than injection moulding or rotational moulding. Whether it’s a branded, colorful, consumer-facing piece or a functional industrial equipment cover, the plastic sheet moulding process of vacuum forming gives the flexibility of design and the durability needed to protect OEM equipment.